Automotive Wiring Harness Market Size, Share, Demand, and Forecast 2025-2033

Market Overview:

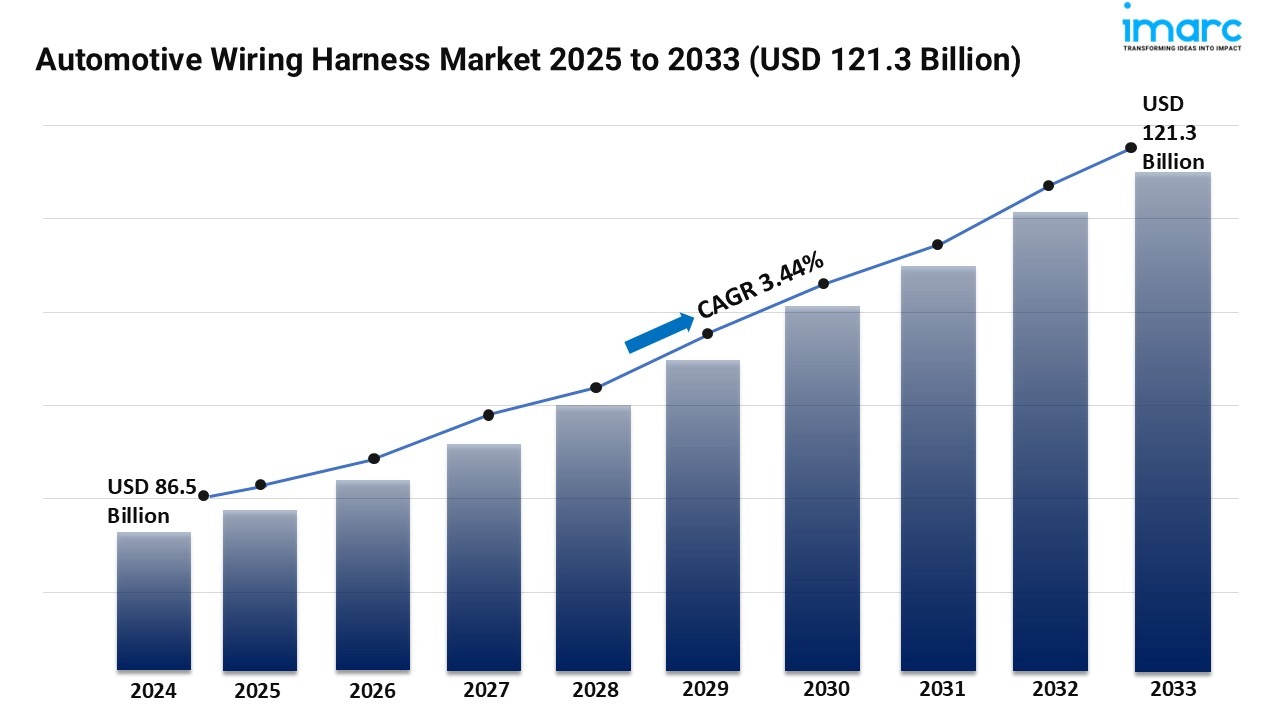

The automotive wiring harness market is experiencing rapid growth, driven by electrification & advanced connectivity, miniaturization & material optimization, and regionalization & supply chain resilience. According to IMARC Group’s latest research publication, “Automotive Wiring Harness Market Size, Share, and Trends by Application, Material Type, Transmission Type, Vehicle Type, Category, Component, Region and Forecast 2025-2033“, The global automotive wiring harness market size was valued at USD 86.5 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 121.3 Billion by 2033, exhibiting a CAGR of 3.44% during 2025-2033.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Grab a sample PDF of this report: https://www.imarcgroup.com/automotive-wiring-harness-market/requestsample

Our report includes:

- Market Dynamics

- Market Trends And Market Outlook

- Competitive Analysis

- Industry Segmentation

- Strategic Recommendations

Factors Affecting the Growth of the Automotive Wiring Harness Industry:

- Electrification & Advanced Connectivity:

The automotive wiring harness market undergoes a deep exchange in speedy electrification of cars and cumbersome demand for superior connection facilities. There is gasoline from the exponential boom of dynamic electric cars (EV), hybrid electric automobiles (raised) and plug-in hybrid electric powered cars (PHEV), all of which require complicated wiring to manipulate high-voltage electricity distribution, battery manage systems and complex electric structure. In addition, the mixing of Advanced Driver-Assessment System (ADAS), infotainment systems and linked car technology will increase notably the quantity and complexity of wiring. The recognition on developing excessive voltage and high -modern twine solutions which can be capable of manage the necessities for electric powertrain, operates innovation in innovation in insulation technologies and connection design. The growing demand for mild and compact wiring is critical to improve the efficiency of the car and decrease the load of the full car. Emphasis on growing robust and reliable wiring networks with strict operation, such as strong temperatures, vibrations and electromagnetic intervention, is important to make sure the protection and performance of the vehicle. Increasing modular wiring designs boom flexibility and decrease the value of meeting, in particular in terms of growing the automobile's optimization.

- Miniaturization & Material Optimization:

The automotive wiring harness seems at a strong tendency for miniature and material optimization driven by way of obligatory to shed pounds at velocity, adapt area use and boom the overall vehicle performance. This is gasoline from the developing call for for dynamic small and slight wiring networks that can be integrated into fast compact car layout. In addition, it is essential to cognizance on growing high demstration materials, together with aluminum conductors and advanced polymer insulation, which improves electrical conductivity with the aid of decreasing weight. Increasing thin wall insulation, micro connections and compact wiring layouts permit a sizeable reduction in size and weight to harness. Emphasis of growing flexible and durable wiring answers that may meet complicated cars Geometric and dynamic operating conditions are essential to ensure lengthy -term reliability. Increasing call for for environmentally friendly and recycled substances runs to apply bio -based totally polymers, permanent production practices and circular economy principles. The development of superior prescription substances and electromagnetic intervention (EMI) suppression technology ensures signal integrity and quickly reduces interference in sensitive digital structures. The integration of superior coating and surface treatment technologies will increase the rust resistance and extends the life of wiring. Increasing automated manufacturing processes and robot mounting improves manufacturing performance and decreases hard work costs, mainly inside the manufacturing of complicated wiring.

- Regionalization & Supply Chain Resilience;

The automotive wiring harness market is experiencing the increasing amount of regionalization and flexibility in Hurry Market Supply Chain, which is motivated to reduce geopolitical risks, reduce the dependence on global supply chains and increase responsibility for regional market needs. It receives fuel from local production and increasing recognition of regional supply chains to reduce dynamic transport, reduce the lead time and ensure stable supply of important components. In addition, it is important to develop strategic partnerships with local suppliers and focus on the establishment of the regional production hub and increase the supply chain flexibility and reduce the effect of potential disturbance. The increasing demand for low lead time and better responsibility is to motivate bus-in-time production and use local storage. The emphasis on developing standardized component design and modular production processes improves flexibility and scalability, which means that manufacturers quickly replaced market requirements. Increasing units and platforms for digital supply chain management improve the visibility and coordination in the price chain. The development of regional centers for cord production of motor vehicles promotes local economic development and employment generation. The increasing demand for durable and morally acidic materials continues to use local suppliers and responsible production practices. Focus on building strong and collaborative relationships with local suppliers, increases the flexibility of the supply chain and promotes long -term partnerships.

Leading Companies Operating in the Global Automotive Wiring Harness Industry:

- Delphi Technologies (BorgWarner Inc.)

- Furukawa Electric Co. Ltd.

- Lear Corporation

- Leoni AG

- Nexans Autoelectric GmbH

- PKC Group Plc (Motherson Sumi Systems Ltd.)

- Samvardhana Motherson Automotive Systems Group B.V.

- Sumitomo Electric Industries Ltd.

- THB Group (AmWINS Group, Inc.)

- YAZAKI Corporation

- YURA Corporation

Automotive Wiring Harness Market Report Segmentation:

Analysis by Application:

- Body Wiring Harness

- Engine Wiring Harness

- Chassis Wiring Harness

- HVAC Wiring Harness

- Sensors Wiring Harness

- Others

Chassis wiring harnesses dominate (34.9% share) due to critical role in powering ABS, suspension, and steering systems, amplified by lightweight material adoption for fuel efficiency.

Analysis by Material Type:

- Copper

- Aluminum

- Others

Copper leads (86.2% share) for superior conductivity and recyclability, driven by EV demand for high-voltage systems and sustainability mandates.

Analysis by Transmission Type:

- Data Transmission

- Electrical Wiring

Electrical wiring holds 81.5% share as backbone for EVs and ADAS, supporting high-voltage power needs and smart connectivity integration.

Analysis by Vehicle Type:

- Two Wheelers

- Passenger Cars

- Commercial Vehicles

Passenger cars lead (52.2% share) via high production volumes, tech integration (ADAS, infotainment), and EV transition requiring complex harness architectures.

Analysis by Category:

- General Wires

- Heat Resistant Wires

- Shielded Wires

- Tubed Wires

General wires lead (40% share) for versatility in lighting/ignition systems, cost efficiency, and insulation advancements enhancing durability.

Analysis by Component:

- Connectors

- Wires

- Terminals

- Others

Wires dominate (42.2% share) as foundational elements for power/signal transmission, with innovations in aluminum alloys and heat-resistant materials.

Regional Insights:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Asia-Pacific leads (37%+ share) due to manufacturing hubs, EV incentives, and cost-efficient supply chains bolstered by rising middle-class demand.

Research Methodology:

The report employs a comprehensive research methodology, combining primary and secondary data sources to validate findings. It includes market assessments, surveys, expert opinions, and data triangulation techniques to ensure accuracy and reliability.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

Post a comment